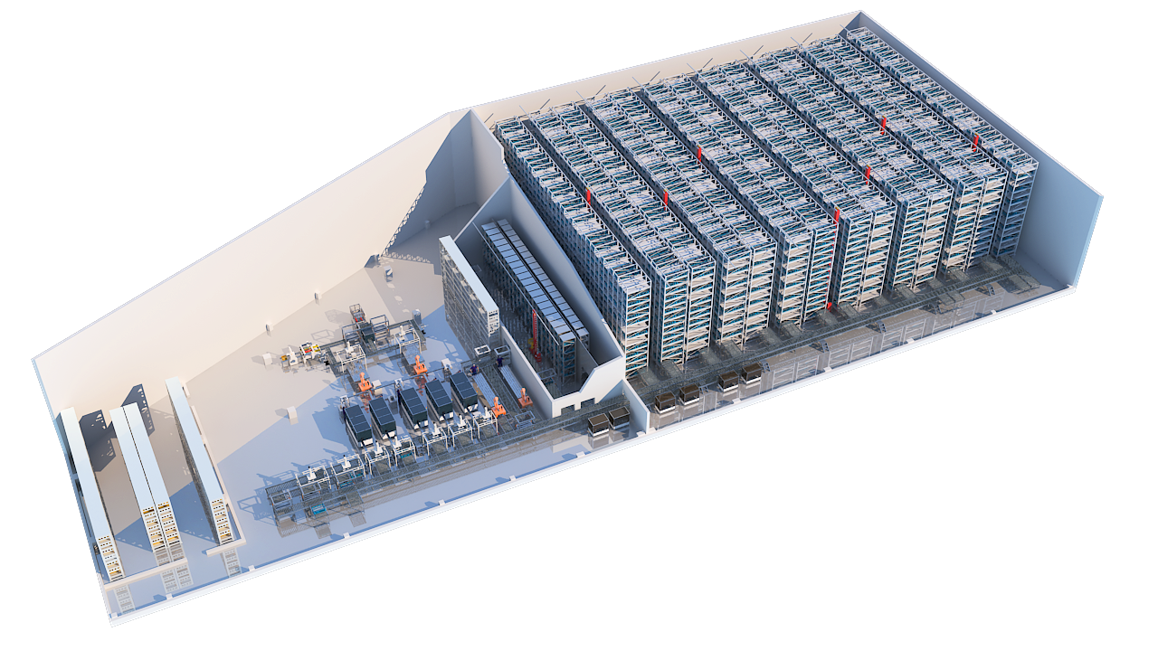

The logistics warehouse is composed of an automated elevated warehouse, a robot automatic feeding area, an OCV retesting area, a NG product charging area, a packaging area, a robot grading area, and a packaging and labeling area.

Project highlights: The front-end robot automatically loads materials, and the capacity dividing stacker adopts a fully servo stacker, greatly improving production efficiency. The backend robot automatically divides files, and the entire process of packaging and labeling is automated, improving work efficiency and reducing personnel labor intensity.

400-12346578

400-12346578 е‘ЁдёҖеҲ°е‘Ёдә”

е‘ЁдёҖеҲ°е‘Ёдә” 123456@qq.com

123456@qq.com